Whether niche product or standard compound - thanks to comprehensive personal consulting, we produce customized solutions for each of your requirements.

Right from the start, you can rely on the expertise of WAGU employees. We support you in developing the optimal rubber compound and in the further processes. From the selection of suitable raw materials and careful compounding to comprehensive services related to your delivery, we take care of your order step by step.

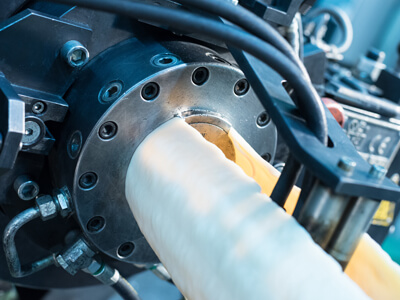

Upon request, this also includes in-depth support during the running-in of the compound in your plants. That way, our employees support you with the production optimization during the transfer, the compression or injection molding as well as the extrusion or lining for corrosion protection and wear protection (surface protection).

We ensure the development of high-quality products through constant quality controls. In our laboratory, our experienced employees test mixtures according to common standards as well as individually agreed parameters of our customers. The weighing and process data of each individual batch are documented.

Standard tests in ongoing productions include measurements of hardness, density and Mooney-viscosity as well as rheology control. Upon request, we can also carry out other relevant tests to the product and application, such as abrasion, tensile tests or media storage.

Each of our batches is documented and comes with a test certificate.

Picture: In the laboratory, new formulations are extensively tested and checked in terms of the physical-mechanical properties that you require to achieve the best possible result.

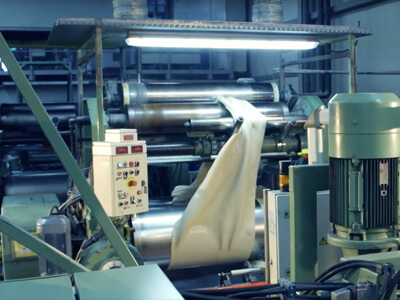

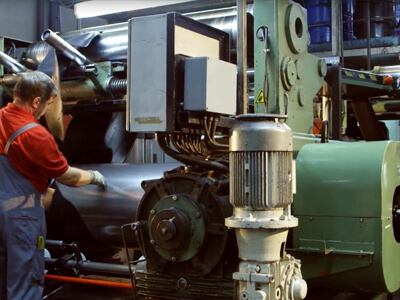

Efficient production lines, automated processes, 100% testing as well as continuous improvements result in our highest quality standards - for all requirements of our customers.

For our rubber compounds, for example, we rely on automated weighing of small components, continuous quality testing using standard and customer-specific test parameters, and detailed documentation of weighing and process data for each individual batch.

We continuously optimize our systems in line with current market requirements and technologies. That way we can offer blending technology on the highest level.

Image: Automated processes, 100% inspection and continuous improvements. Through automatic weighing and detailed documentation, we ensure consistent quality and complete traceability of each batch.

Whether it's a niche product or a standard compound, through constant expansion of our production and continuous process improvements, WAGU rubber technology can easily deliver your individual elastomer quality product.

Four high-performance production lines run at full speed every day to produce sophisticated rubber compounds. Each of our internal mixers is designed to meet different requirements.

guarantee on every product. This detailed testing is ensured by precise documentation of weighing and process data, such as measurements of hardness, density and Mooney viscosity.

After production, we also carry out abrasion tests or tensile tests on request, which we use to check the load-bearing capacity of our products.

![[Translate to English:] Granulat](/fileadmin/user_upload/produkte/Granulat_400_300_01.jpg)