High-quality and customized rubber compounds precisely adapted to the individual requirements of the customer - that is the claim of WAGU Rubber Technology. From laboratory-scale quantities to large-scale series productions, we mix your high-quality rubber compounds for almost any type of application.

Thanks to our many years of experience with rubber, we currently have around 5,000 formulations available for individual compounding for our customers. With around 800 raw materials in stock and other components available at short notice, we can fulfill any order quickly. Of course, we also manufacture according to your own proven formulation under contract compounding.

Thanks to comprehensive and competent consulting, we develop rubber compounds for our customers on the basis of suitable polymers. We supply high-quality compounds for applications of all kinds. In addition to individual WAGU products, we also offer the production of contract compounds.

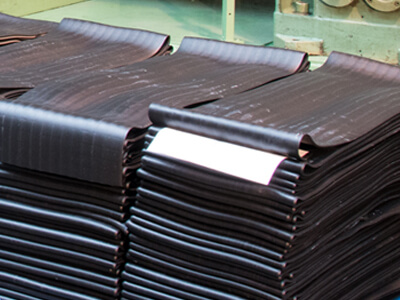

Our rubber compounds are characterized by high quality and a wide range of different polymers and delivery forms. On four high-performance internal mixers, all formulations are produced to the highest standards and purity levels. We guarantee perfect quality through 100% testing. We only deliver, when the product fully meets your requirements.

- Continuous feeding strips (mesh box or carton)

- Strips rolled on spool

- Wig-Wag skins (also perforated)

- Single skins with and without release agent

- Granules

- Extruded webs

- Calendered webs

- Vulcanized webs (with and without fabric insert)

- Unvulcanized profiles

- Prefabricated blanks

- Perforated skins

Please ask us for further processing and delivery possibilities!

Whether molded parts, roll covers, linings, hoses, diaphragms or handmade confection articles - WAGU rubber compounds are used in almost every sector of technical elastomer processing. In production, we flexibly adapt to specific product requirements and technical demands.

An overview of our current portfolio - we would also be happy to take on your individual challenge:

To ensure the high quality of our products, WAGU only uses raw materials from approved, released suppliers. Upon delivery, our raw materials go through a conscientious quality assurance and are only released for further processing after passing our tests.

Inventory-optimized storage capacities and raw materials that can be delivered at short notice enable an efficient production. In addition, automated processes and individual test parameters ensure maximum reproducibility of the compounds produced for you.

| Ethylene Propylene Rubber | Abbreviation according to DIN ISO 1629 (ASTM) | Features | Cold resistance [°C] | Heat Resistance [°C] | Maximum continuous load [°C] |

| Natural Rubber | NR | Excellent mechanical features: good elasticity, high strength, low abrasion, good dynamic behavior | -50 | + 80 | + 70 |

| Polyisoprene Rubber | IR | Similar NR, good hysteresis properties | -50 | + 90 | + 80 |

| Butadiene Rubber | BR | Low abrasion, very high elasticity, lower hysteresis | -60 | + 90 | + 80 |

Styrene Butadiene Rubber | SBR | Low abrasion, good vulcanization plateau, good processability | -40 | + 100 | + 90 |

| Chloroprene Rubber | CR | Weather resistant, flame retardant, swell resistant to certain oils, greases and solvents | -40 | + 110 | + 100 |

| Nitrile Rubber | NBR | Good oil resistance (swelling resistance to non-polar media), good mechanical properties, good gas and air impermeability, suitable for conductive compounds | -40 | + 120 | + 100 |

| Hydrogenated Nitrile Rubber | HNBR | Good oil resistance and good heat resistance, very good mechanical properties (high strength, low abrasion). | -35 | + 160 | + 150 |

| Carboxylated Nitrile Rubber | XNBR | Increased wear resistance compared to NBR | -40 | + 120 | + 100 |

| Butyl Rubber | IIR/BIIR/CIIR | Excellent gas tightness, low swelling in polar media, electrically insulating, brominated (BIIR) and chlorinated (CIIR) grades available | -40 | + 130 | + 120 |

| Norbornene Rubber | NOR (PNR) | Low hardness settings possible with relatively high strengths, good damping properties | -40 | + 80 | + 80 |

| Ethylene Propylene Diene Rubber | EPDM | Very good aging resistance, ozone resistant, acid and alkali resistant, steam resistant, electrically insulating, resistant to polar media | -45 | + 150 | + 130 |

| Ethylene Propylene Rubber | EPM | Very good aging resistance, ozone resistant, acid and alkali resistant, electrically insulating, resistant to polar media | -45 | + 150 | + 130 |

| Chlorinated Polyethylene | CM (CPE) | Excellent ozone and weathering resistance, flame retardant, oil resistant, electrically insulating | -40 | + 150 | + 130 |

| Chlorosulfonated polyethylene | CSM | Excellent weather resistance, color stable, flame retardant, acid and alkali resistant, electrically insulating | -35 | + 150 | + 120 |

| Ethylene Vinyl-Acetate Rubber | EVM | Good compression set, high flexibility, medium oil resistance | -25 | + 130 | + 105 |

| Acrylic Rubber | ACM | Very good oil resistance (swelling resistance to non-polar media), ozone resistant | -30 | + 160 | + 150 |

| Ethylene acrylate rubber | AEM | Good oil resistance and good heat resistance, low compression set | -40 | + 175 | + 170 |

| Tetrafluoroethylene-Propylene Rubber | FEPM | Very good resistance to strong acids and alkalis and very good heat resistance, excellent oil resistance | -30 | + 230 | + 200 |

| Fluoro Rubber | FKM (FPM) | Excellent resistance to non-polar solvents (e.g. gasoline) and very good heat resistance, low compression set | -40 | + 250 | + 200 |

| Perfluoro Rubber | FFKM | Excellent chemical resistance, applicability under extreme conditions, low compression set | -15 | + 350 | + 315 |

| Epichlorohydrin Rubber | ECO | Flame retardant, oil and solvent resistant, ozone resistant, low gas permeability, good flexural strength | -40 | + 135 | + 120 |

| Polyurethane Rubber | AU/EU | Very low abrasion, very good mechanical properties (tear strength, tear propagation resistance), resistance to various solvents | -30 | + 100 | + 80 |

Here you will find everything about our products

For more than 50 years, WAGU rubber technology has been a proven manufacturer of rubber compounds. With our equipment we produce individual batches with up to 200kg.

Experienced employees, high-quality equipment and the German production standards allows us to maintain our high quality standards and enable us to guarantee a fast delivery.